Pioneering

3D-Printed Propulsion

NEAL Aerospace will be the first student group to successfully design and test a hybrid rocket engine utilizing a 3D-printed ABS fuel grain. Our Remus engine targets 2.5 kN thrust, redefining what's possible in student rocketry.

Modular Testing

Infrastructure

Ostia is our modular, multi-vehicle test stand. Designed for flexibility, it allows for rapid and safe testing of various propulsion systems, including our Remus hybrid rocket.

Monopropellant

Innovation

Our proprietary Cyclopes engine represents the future of compact, efficient propulsion systems for small-scale aerospace applications.

Autonomous

Flight Systems

Hyperion is our advanced drone platform, designed to test cutting-edge propulsion technologies in real-world flight conditions.

Our Achievements

Remus Rocket

The world's first undergraduate student-designed hybrid rocket engine featuring a revolutionary 3D-printed fuel grain system.

Technical Specifications

Propulsion System

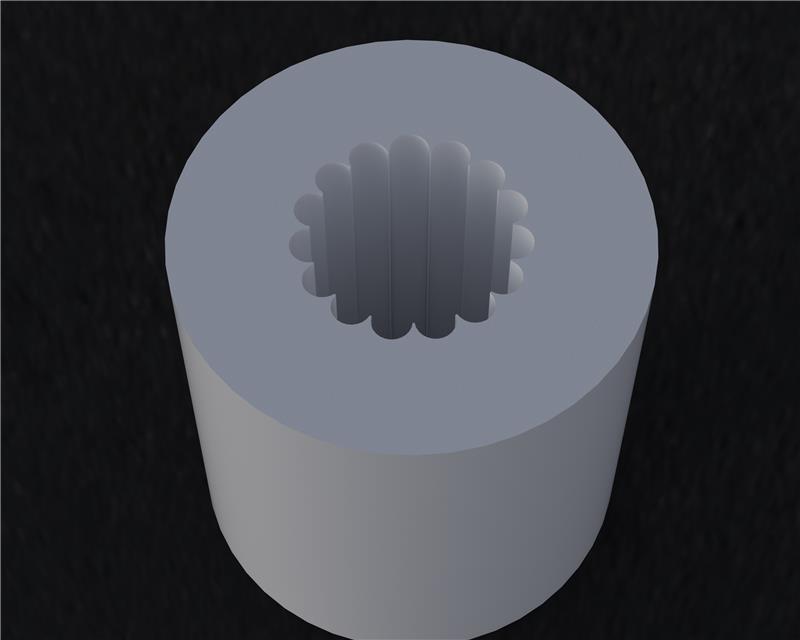

Hybrid rocket engine using a 3D-printed acrylonitrile butadiene styrene (ABS) fuel grain with nitrous oxide (N₂O) oxidizer

Peak Thrust

2.5 kN (2,500 Newtons) design goal

Fuel Grain Geometry

3-inch diameter, 15-inch length optimized for maximum performance

Specific Impulse

227 seconds, optimized for hybrid propulsion efficiency

Innovation

First successful implementation of FDM 3D-printed fuel grain in a student rocket engine

Remus engine cutaway showing internal fuel grain geometry

Fuel Grain

Intricate Geometries

Easy to implement complex grain shapes with additive manufacturing.

Repeatable & Accurate

3D printing delivers highly repeatable grains with tight tolerances.

Rapid Optimization

Print–test–reprint workflow makes it easy to iterate toward optimal performance versus traditional casting.

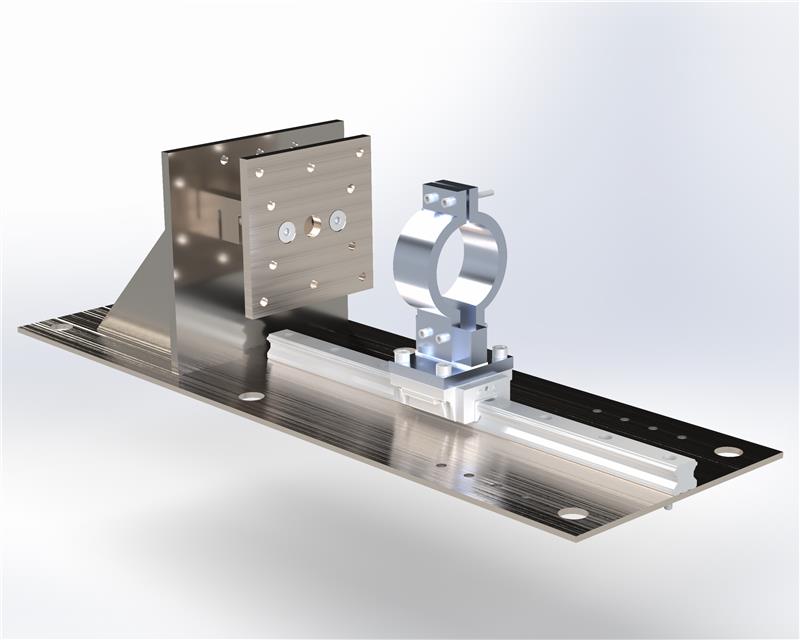

Ostia Test Stand

A state-of-the-art modular testing infrastructure designed for safe and efficient validation of multiple propulsion systems.

Mobile Testing Platform

Ostia is a mobile rocket test stand designed to accommodate various propulsion systems in a horizontal configuration. The system features two main components: a robust steel mount for propulsion devices and a dedicated fluids cart housing all necessary plumbing infrastructure.

Horizontal Test Configuration

Optimized mounting system for safe and efficient engine testing

Advanced Data Acquisition

Real-time monitoring of thrust, pressure, temperature, and vibrational data

Mobile & Modular

Portable design with integrated fluids cart for field testing flexibility

Multi-System Compatibility

Engineered to support various propulsion systems from hybrids to monopropellants

Data Acquisition Capabilities

Thrust Measurement

Precision load cells for accurate thrust profiling

Temperature Data

Multi-point thermal monitoring systems

Pressure Sensing

Real-time chamber and line pressure tracking

Vibration Analysis

Advanced vibrational data collection

Hyperion Drone

An advanced autonomous flight platform designed to validate innovative propulsion systems in real-world conditions.

Mission Profile

Hyperion serves as our testbed for integrating cutting-edge propulsion technologies with autonomous flight control systems. The platform will eventually incorporate our Cyclopes monopropellant engine for extended flight capabilities.

Autonomous Navigation

Advanced flight control algorithms for stable, reliable operation

Telemetry Systems

Real-time data transmission for performance monitoring

Modular Payload

Interchangeable systems for different testing requirements

Hyperion platform with integrated sensor suite

Platform Specifications

Flight Control

Custom-developed autopilot system with redundant safety features and GPS/IMU integration

Power System

High-capacity LiPo battery system with intelligent power management

Communication

Long-range telemetry link for command and control up to 5km

Integration

Designed for future integration with Cyclopes propulsion system

Cyclopes Engine

A revolutionary monopropellant propulsion system designed for compact, efficient thrust generation.

The Future of Compact Propulsion

The Cyclopes engine represents our most ambitious project yet. Using advanced monopropellant chemistry and precision-engineered components, this engine will power the next generation of small-scale aerospace applications.

Compact Design

Optimized for integration with small aerial platforms while maintaining significant thrust output

High Efficiency

Advanced catalyst systems for maximum propellant utilization and specific impulse

Rapid Response

Quick ignition and throttle response for precise flight control applications

Safety First

Designed with multiple safety features and fail-safe mechanisms

About NEAL Aerospace

Pioneering the future of aerospace technology at Georgia Tech.

Our Mission

NEAL Aerospace is dedicated to pushing the boundaries of student-led aerospace research. We strive to develop innovative propulsion systems and aerospace technologies while providing hands-on engineering experience to Georgia Tech students.

Our Story

Founded at Georgia Institute of Technology, NEAL Aerospace began with a simple but ambitious goal: to design and test a hybrid rocket engine using cutting-edge 3D printing technology.

What started as a small group of passionate engineering students has grown into a multidisciplinary team tackling some of the most challenging problems in modern aerospace engineering.

Our achievement as the first student group to successfully test a 3D-printed fuel grain hybrid rocket engine marked a major milestone, but it's just the beginning of our journey.

NEAL Aerospace team at Georgia Tech

Our Teams

Propulsion

Engine design, testing, and optimization

Structures

Airframe and component design

Avionics

Flight computers and telemetry systems

Recovery

Parachute and safety systems

Our Values

Innovation

Pushing boundaries with creative solutions to complex engineering challenges

Safety

Maintaining the highest safety standards in all testing and operations

Excellence

Striving for technical excellence and continuous improvement

Want to Join Our Team?

Our Sponsors

Our achievements are made possible by the generous support of our sponsors and partners.

Thank You To Our Partners

We are grateful to all our sponsors for their continued support. Your contributions enable us to push the boundaries of student aerospace research, develop innovative 3D-printed propulsion systems, and achieve groundbreaking milestones in hybrid rocket technology.

Platinum Sponsors

Platinum Tier Sponsor

Platinum Tier Sponsor

Gold Sponsors

Silver Sponsors

Become a Sponsor

Support the next generation of aerospace engineers and be part of groundbreaking research.

Platinum

$10,000+

- • Logo on all vehicles

- • Featured in press releases

- • Test site visits

- • Quarterly reports

Gold

$5,000+

- • Logo on website

- • Social media recognition

- • Semi-annual reports

Silver

$1,000+

- • Website listing

- • Newsletter updates

- • Annual report

Interested in Sponsoring?

Contact us to discuss sponsorship opportunities and help fuel our next milestones.

Join NEAL Aerospace

Be part of something extraordinary. Join Georgia Tech's premier aerospace research organization.

Why Join NEAL?

Hands-On Experience

Work on real aerospace projects from design to test

Learn & Grow

Develop technical skills beyond the classroom

Build Network

Connect with like-minded engineers and industry professionals

Make Impact

Contribute to cutting-edge aerospace research

Open Positions

Electrical & Hardware (Data Systems)

Data & Electronics

Build and maintain data acquisition, sensors, and test electronics (DAQ, wiring, telemetry). Comfortable with hardware bring-up and basic scripting.

Business & Operations

Operations Team

Manage sponsorships, outreach, and team operations. Strong communication and organizational skills required.

Financial Officer

Operations Team

Handle SOFO purchasing, budgeting, and reimbursements. Coordinate with suppliers and ensure compliant spend tracking.

Application Process

Apply

Submit your application online

Interview

Meet with team leads

Onboard

Complete safety training

Start

Begin working on projects

Requirements

- ✓ Currently enrolled at Georgia Institute of Technology

- ✓ Passion for aerospace and engineering

- ✓ Commitment to team meetings and project deadlines

- ✓ Willingness to learn and collaborate

- • All majors welcome - we value diverse perspectives!

Ready to Apply?

Recruitment opens at the beginning of each semester

Media Gallery

Explore our latest tests, launches, and team moments.

Featured

Remus Engine Test - Full Duration Burn

Our most successful test to date, achieving full design burn duration with stable combustion.

Photo Gallery

Static fire test at Georgia Tech facility

Team assembling Remus engine

Ostia test stand setup

3D printing fuel grain components

Preparing for test launch

NEAL Aerospace team 2024

Press & News

Students Achieve First for 3D-Printed Rocket Engine

NEAL Aerospace becomes the first student organization to successfully test a hybrid rocket engine with 3D-printed fuel grain...

Read More →Innovation in Student Rocketry

How one university team is pushing the boundaries of additive manufacturing in aerospace applications...

Read More →Next Generation Propulsion Systems

NEAL Aerospace team discusses their groundbreaking work in hybrid rocket technology and future plans...

Read More →Latest Test

Remus Hybrid Engine - Full Duration Static Fire

November 15, 2024

Test Summary

NEAL Aerospace successfully completed a full-duration static fire test of the Remus hybrid rocket engine at our Georgia Tech testing facility. The test marked a significant milestone, achieving all primary objectives and demonstrating the viability of our revolutionary 3D-printed ABS fuel grain technology with nitrous oxide oxidizer.

The engine burned for the full design duration, producing stable thrust throughout the burn with excellent combustion characteristics. The 3D-printed fuel grain maintained structural integrity under extreme conditions, validating our innovative manufacturing approach. All safety systems performed flawlessly, and our comprehensive data acquisition systems captured high-quality telemetry throughout the test.

Key Results

Peak Thrust

Burn Duration

Specific Impulse

Success Rate

Test Objectives

Validate 3D-Printed ABS Fuel Grain

Achieved: First-ever student test of a 3D-printed ABS fuel grain. The grain maintained structural integrity throughout burn with excellent regression characteristics and combustion stability.

Demonstrate Full Duration Burn

Achieved: Engine operated for full design duration with stable combustion and thrust output.

Test Data Acquisition Systems

Achieved: All sensors and telemetry systems functioned correctly, providing comprehensive data set.

Validate Safety Systems

Achieved: All safety protocols and emergency systems performed as designed.

Data Analysis

Thrust vs. Time

Thrust profile showing stable combustion throughout burn duration

Chamber Pressure

Consistent pressure indicating efficient propellant flow and combustion

What's Next

Following this successful test, the team is now focused on scaling up the design for higher thrust applications and preparing for flight testing. We're also conducting detailed analysis of the telemetry data to optimize future iterations.

Q1 2025

Scaled engine design and testing

Q2 2025

Flight vehicle integration

Q3 2025

First flight attempt

Want to See More?

Contact Us

Get in touch for sponsorships, media inquiries, recruitment, or general questions.

Quick Links

Sponsorships

Learn about partnership opportunities

Join the Team

Explore open positions

Media Kit

Download press materials

About Us

Learn about our mission